OIL AND GAS

SecureSample provides a solution for Oil and Gas companies to safely and accurately monitor the composition of their produced water and oil.

The problem

Contamination in fluid sampling within the oil and gas industry is a significant issue that can have profound impacts on various aspects of operations, safety, and environmental stewardship.

01

Data Accuracy

Accurate fluid sampling is crucial for making informed decisions regarding reservoir management, production optimization, and environmental monitoring. Contamination can skew analytical results, leading to inaccuracies in data interpretation and potentially costly errors in decision-making processes.

03

Regulatory Compliance

The oil and gas industry is subject to stringent regulations governing fluid sampling and environmental protection. Contamination incidents may result in non-compliance with regulatory standards, leading to fines, penalties, and legal liabilities for companies.

05

Public Perception

Contamination incidents in the oil and gas industry can erode public trust and confidence in the sector's ability to operate responsibly and sustainably. Public perception of contamination issues can influence regulatory scrutiny, investor confidence, and stakeholder engagement, affecting industry reputation and social license to operate.

02

Environmental and Health Risks

Contamination in fluid samples can pose risks to the environment and human health. For example, inaccurate measurements of pollutants in produced water or drilling fluids may result in improper disposal practices, leading to contamination of soil, water bodies, and ecosystems. Similarly, inaccurate assessments of gas composition can pose safety risks to workers and nearby communities.

04

Operational Efficiency

Contamination-related errors in fluid sampling can disrupt operations and lead to inefficiencies in production processes. For example, inaccurate measurements of fluid properties may result in suboptimal reservoir management strategies or improper treatment of produced water, impacting operational performance and profitability.

06

Resource Wastage

Contamination in fluid sampling often necessitates additional sampling and analysis efforts to obtain accurate data, leading to wasted resources such as time, labor, and equipment. Redundant sampling activities not only increase operational costs but also delay decision-making and project timelines, impacting overall project efficiency.

The solution

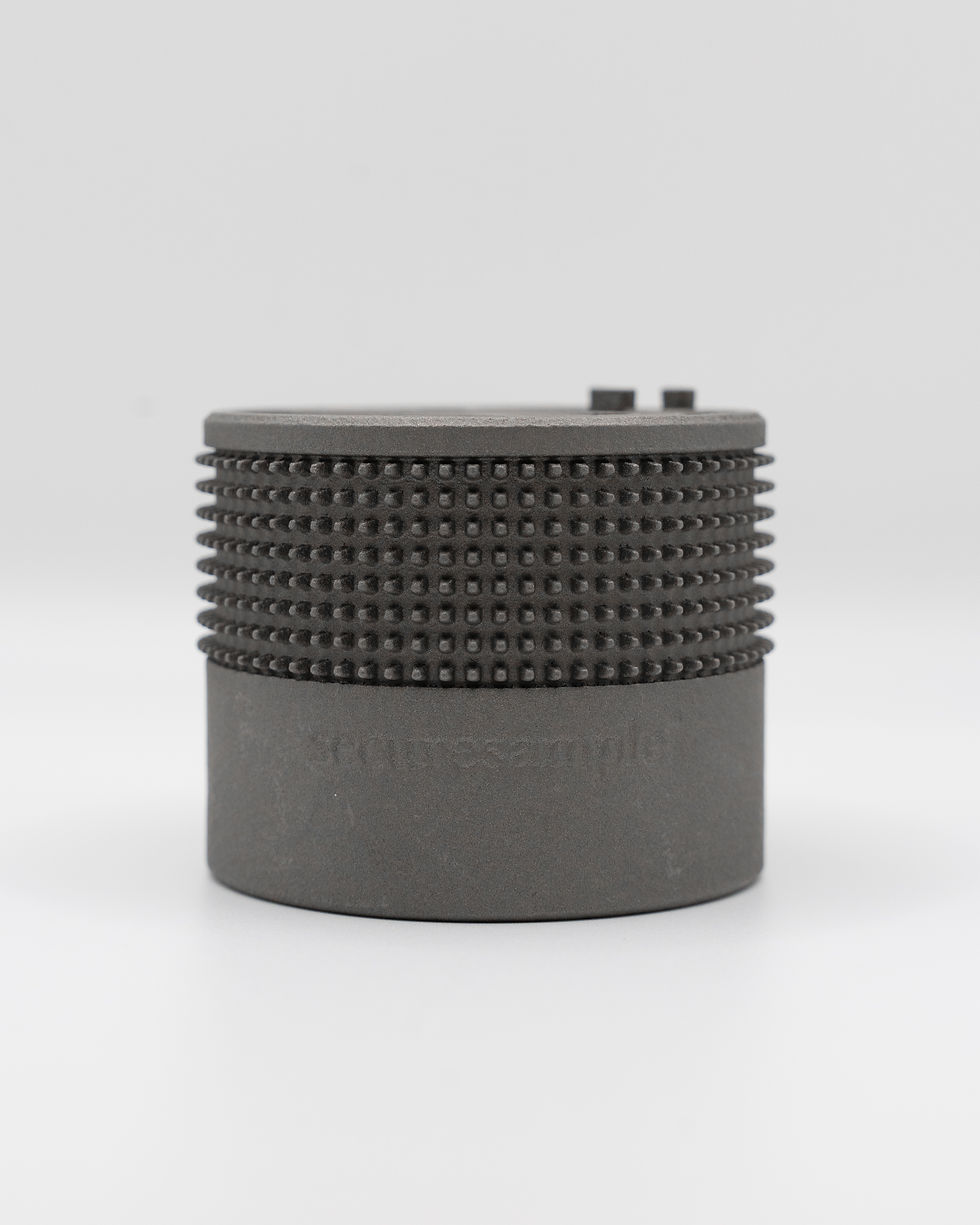

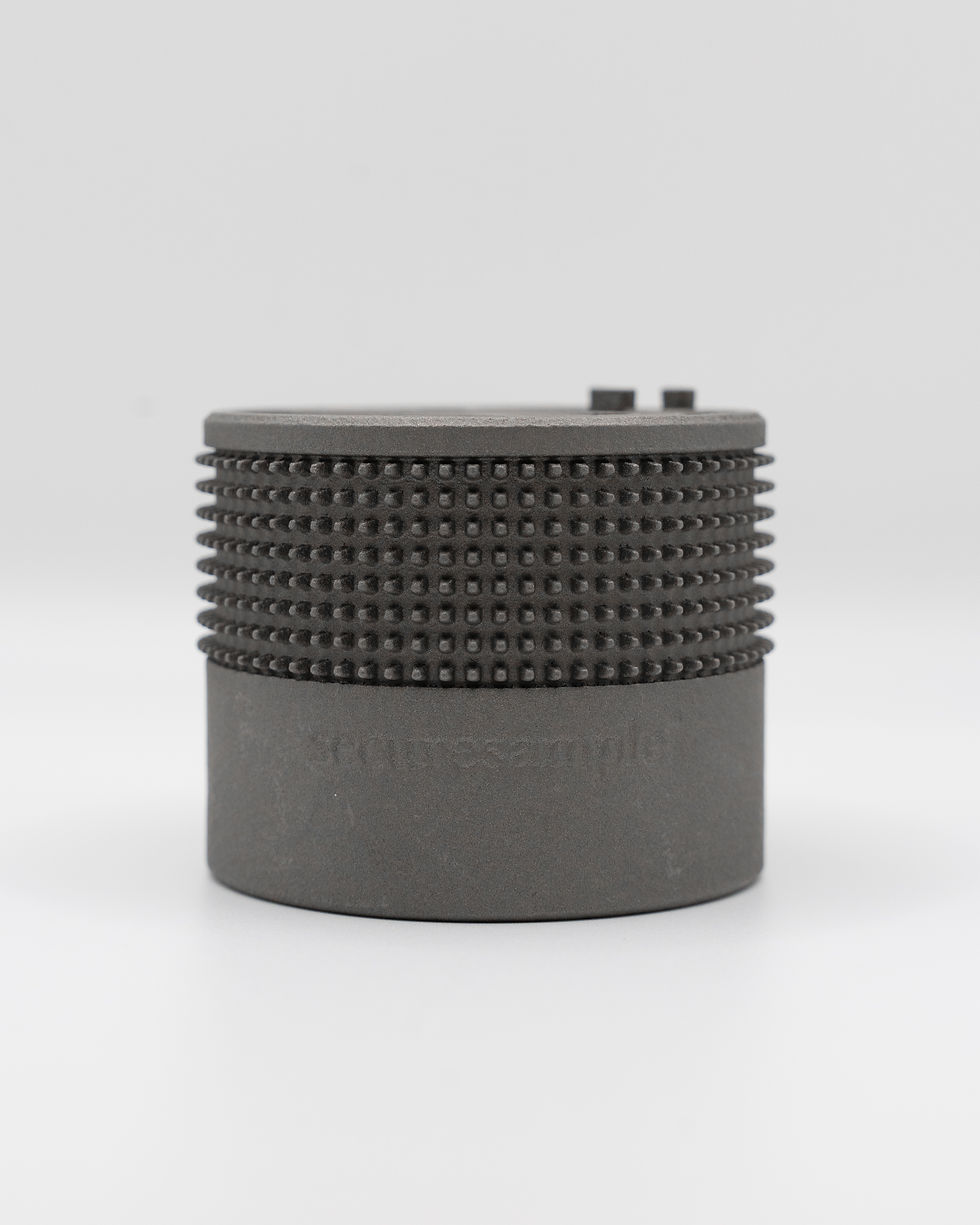

SecureSample's patent-pending technology offers a variety of features that combat challenges in fluid sampling.

Safety

Elimination of Static Charge on Operator

SS Straightline Adapter with Electrostatic Dissipative (ESD) Coating: This coating dissipates static charge from the operator, reducing the risk of fire and H2S exposure in volatile environments.

Grounding Wristband Connection

The adapter includes a connection for a grounding wristband, ensuring the operator's charge is discharged safely.

Four Redundant Safety Mechanisms

-

Operator touches the fluid collection adapter with ESD coating.

-

Operator uses a grounding wristband connected to the fluid collection adapter.

-

Secondary grounding wire connects the fluid sampling adapter to the grounded metal bucket.

-

Adapter is grounded to a water tank via brass metal housing.

Cleanliness at Collection Site

Spill Elimination

The SS Straightline Adapter and SS Cap are designed to eliminate spills during fluid collection

Integrity of Fluid Samples

Self-Sealing Cap (SS Cap)

This tamper-proof, single-use cap seals the sample from the environment, maintaining its integrity.

Sample Withdrawal and Additive Injection

Samples can be withdrawn with a standard syringe needle, and additives can be injected without compromising the sealed environment.

Enhanced Safety for Transport and Laboratory Handling

The sealed cap ensures additional safety during transportation and handling by lab technicians.

Customizable Adapter Features

Modifiable Design

The size of the adapter, vent hose opening, and threading options can be customized to meet your needs.

The importance of water testing in the oil and gas industry

Water testing is crucial to the oil and gas industry for environmental stewardship, operational efficiency, regulatory compliance, and risk management. By monitoring and managing water quality throughout the production lifecycle, operators can minimize environmental impacts, protect assets, and maintain sustainable operations.

01

Environmental Compliance

The industry is subject to strict environmental regulations regarding water usage, discharge, and contamination. Water testing helps ensure compliance with these regulations by monitoring the quality of water sources, such as surface water bodies and groundwater aquifers, that may be impacted by oil and gas operations.

03

Produced Water Management

During oil and gas production, water naturally present in underground reservoirs, known as produced water, is brought to the surface along with oil and gas. Produced water may contain various contaminants, including hydrocarbons, heavy metals, and salts. Water testing helps characterize the composition of produced water, determine appropriate treatment methods, and ensure compliance with disposal regulations.

05

Reservoir Management

Water influx into oil and gas reservoirs can impact production rates and reservoir performance. Water testing provides valuable information on the source, composition, and movement of water within reservoirs, helping operators optimize production strategies, mitigate formation damage, and maximize hydrocarbon recovery.

02

Fracking Operations

Hydraulic fracturing, or fracking, is a common technique used to extract oil and gas from shale formations. Fracking operations require large volumes of water, often mixed with chemicals, sand, and other additives. Water testing is critical to assess the suitability of water sources for fracking, monitor the quality of water used in the process, and manage potential environmental risks associated with wastewater disposal.

04

Corrosion Control

Water is commonly used in oil and gas production facilities for processes such as cooling, drilling, and steam generation. However, water can also promote corrosion in equipment and pipelines, leading to safety hazards and production downtime. Water testing helps identify corrosive agents and assess the effectiveness of corrosion inhibition strategies to protect infrastructure and ensure operational reliability.

06

Risk Management

Water quality issues, such as contamination from chemicals, bacteria, or naturally occurring substances like hydrogen sulfide, can pose health and safety risks to workers and nearby communities. Regular water testing is essential for identifying potential risks, implementing appropriate mitigation measures, and ensuring the health and safety of personnel and the surrounding environment.

CONTACT

Get in touch

SecureSample is dedicated to helping you increase efficiency, safety and accuracy in fluid sampling.

By submitting this form, you authorize us to disclose your information in accordance with the SecureSample Privacy Policy. You also authorize SecureSample to contact you to discuss the products and services.